Medical Autoclave Types & Working

- Skill Biomed

- Apr 24, 2020

- 3 min read

Sterilisation Autoclave Types, Application & Working

Autoclaves provide a physical method for disinfection and sterilization. Autoclaves work with a combination of steam, pressure and time. Autoclaves operate at high temperature and pressure in order to kill microorganisms and spores.

An autoclave is a pressure chamber that is used to Sterilise equipment and supplies. When these items are placed inside the autoclave they are exposed to high temperature steam (usually around 132 degrees Celsius or 270 degrees Fahrenheit) for about twenty minutes.

Types of Autoclaves

The European standard DIN EN ISO 13060 divides Autoclaves into three different types:

Class N

Class B

Class S

Class N Autoclaves

Class N autoclaves are compact, and they are for sterilizing simple materials. The letter “N” stands for “naked solid products”. Therefore, these autoclaves cannot be used to sterilize textiles, porous loads, hollow items or even products in pouches, as the cycles do not have the right characteristics to pass specific physical tests.A Class N Sterilizer or also known as a positive pressure displacement autoclave uses steam to displace all the air in the sterilization chamber before sterilization. The steam is released into a chamber using an independent steam generator in a pressurized blast, forcing the air out through the drain hole and starting the sterilization process. This results in a more accurate displacement of air than a downward displacement unit which uses a heating element that is submerged in water.

Class B Autoclaves

Class B autoclaves are compact, but their performance levels are comparable to those of the largest machines in hospitals. The letter “B” stands for “big small sterilizers”, because they are small machines that offer big performance.

A Class B Sterilizer is a steam sterilizer that uses a vacuum pump to remove air/steam mixtures from the chamber prior to sterilization cycle beginning. This process can remove 99% of the air inside of the chamber before the temperature and pressure increases to its necessary parameters.

This dynamic air removal provides the necessary conditions to sterilize any load type, including porous or hollow materials, products in pouches, textiles and hollow items like wands, turbines, handpieces and tips.

S Class

Class S autoclaves can accommodate larger loads and bigger instruments without compromising on performance. With effective air-cooling systems and integrated water storage, these autoclaves can be operated without a water hook-up, though they also have a feature which enables them to connect to a demineralized water treatment unit.

Class S autoclaves are compact, and Type S covers all the other types of autoclaves. Essentially, it is an intermediate class between Type N and Type B autoclaves and the characteristics are not defined by any standards. Only the manufacturers can provide details of their performance capabilities, which are established by specific tests.

Class S Autoclaves are suitable for sterilizing wrapped and unwrapped solid instruments that can withstand pressure steam.

Working of Class B Autoclave

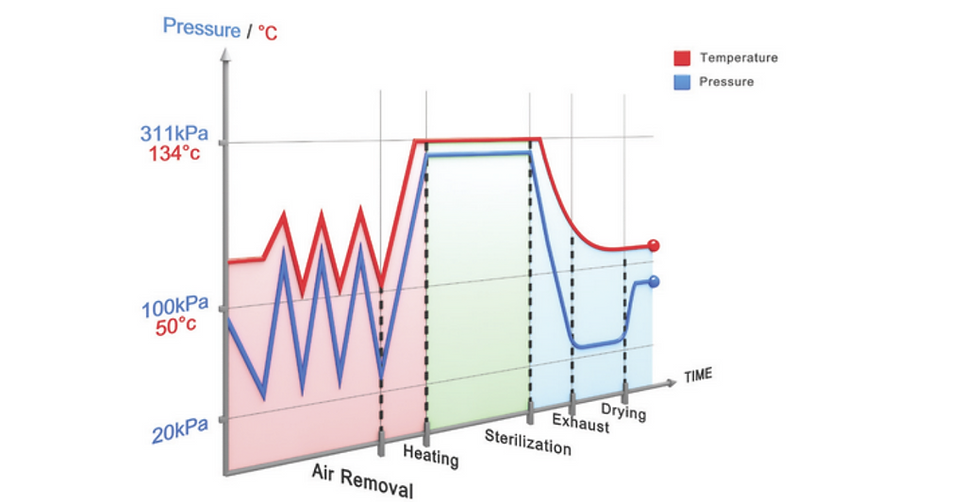

Step 1- Air Removal: Vacuum pump removes air from the chamber with short pulses. This conditioning process of the chamber for sterilization will remove 99% of the air inside the chamber.

Step 2 – Heating: Once all the air is removed, the steam generator will inject small burst of steam into the chamber until the pressure and temperature reaches the appropriate parameters to start the sterilization time (holding time).

Step 3 – Sterilization: Once the temperature and pressure are reached the system will maintain this temperature and pressure throughout the sterilization time. This is the stage where the sterilization takes place.

Step 4 – Exhaust: The exhaust valve/solenoid valve will open to release the pressure/steam inside the chamber until the pressure is equal to atmospheric pressure.

Step 5 – Drying: After all the air is exhausted after the sterilization cycle. The vacuum pump will again pump out all the moisture and steam from the load until the load is completely dry. The heating elements around the chamber will stay on to allow the water to evaporate into gas and be pumped out by the vacuum.

Step 6- Completion: After the drying is done, the cycle is complete, and you can open the door.

Features of Class B Autoclaves

Class B Steam Sterilizer with pre/post vacuum

Better penetration for hollow and porous instruments

Faster Sterilization Times and Cycle

5 Programmed Sterilisation Cycles: Unwrapped, Wrapped, Plastics, Textile, Prions and 3 Test Programs (B&D, Vacuum Test, Helix Test)

Solid Steel Construction

Independent Steam Generator for positive pressure displacement

Easy to repair – Quality Parts Made in Europe

Optional Printer

USB Port for Recording Cycles

Triple Door Protection System – Prevents door from opening during Cycles and cycle from starting if door is not closed

Pressure Safety valve

Learning Material can be Download in Pdf from shared Files

Nice article 😊